Rigid sometimes abbreviated as rpvc and flexible.

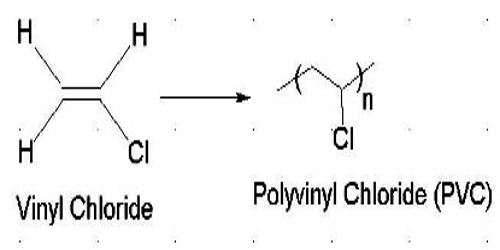

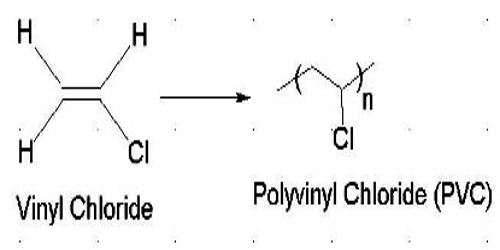

Vinyl chloride polymer thermoplast.

Polyvinyl chloride commonly referred to as pvc or vinyl is the world s 3 rd most synthesised thermoplastic material.

Polyvinyl chloride pvc or vinyl is an economical and versatile thermoplastic polymer widely used in building and construction industry to produce door and window profiles pipes drinking and wastewater wire and cable insulation medical devices etc.

Pvc is the world s third most widely produced synthetic plastic polymer after polyethylene and polypropylene about 40 million tons of pvc are produced each year.

Most thermoplastics have a high molecular weight the polymer chains associate by intermolecular forces which weaken rapidly with increased temperature yielding a viscous liquid in this state thermoplastics may be reshaped.

Its most well known application is the formation of pvc pipes in the building and construction industry but the benefits of pvc extend far beyond this into the medical electrical and protective clothing sectors.

Generally upvc can be used at temperatures up to 60 c.

Poly vinyl chloride pvc in particular has been subjected to such modification by a variety of material and its use in electrical applications especially in rubberized form is well known 4 with the advent of thermoplastic elastomers one would expect that the conventional materials in pvc rubber blends would be replaced by new components.

Pvc comes in two basic forms.

A thermoplastic or thermosoftening plastic is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Us4670494a us06 760 669 us76066985a us4670494a us 4670494 a us4670494 a us 4670494a us 76066985 a us76066985 a us 76066985a us 4670494 a us4670494 a us 4670494a authority us united states prior art keywords parts per resin per hundred amount composition prior art date 1985 07 30 legal status the legal status is an assumption and is not a legal conclusion.

It is one of the most analyzed tested and versatile materials on the market.

Thermoplastic moulding materials for the production of packaging materials for foodstuffs which consist of or are based on vinyl chloride polymers and contain monoalkyl tin stabilizers.

It is one of the most durable low cost films and is resistant to many chemicals.

Polyvinylchloride pvc or vinyl is a thermoplastic and the third largest production polymer in the world.